WHAT ARE THE STEPS IN CRIMPING RJ-45 CONNECTOR?

The crimping process will deform the strands of the wire so that there is a gas-tight joint. Not only will this provide the greatest surface area for electrical contact, but it also prevents oxygen or moisture from reaching the metal of the wire and terminal, reducing the possibility of corrosion.

1. Cut into

the outer sheath of the cable with a pair of scissors. Take

a pair of scissors and gently cut into the plastic sheath about 1 inch

(25 mm) from the end of the cable. Make sure you don’t cut into the wires

inside. When the scissors penetrate the sheath, rotate the cable and scissors

to create a cut around the cable. Then, stick your fingertips under the sheath

and pull it off towards the end.

Tip: If you don’t have scissors, you can

use a utility knife to cut away the outer sheath. But be careful not to cut the

wires inside.

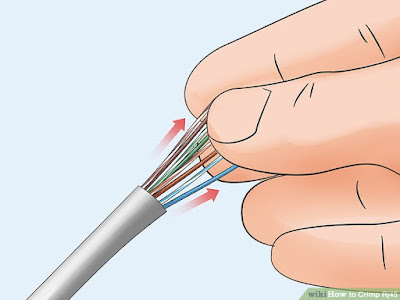

2. Separate and straighten out the small

wires in the cable. Use your fingers to

untwist and straighten the exposed wires after you remove the sheath. If there

is a plastic core or wire separator, cut it away with your scissors.

3. Put the wires in the right order. Arrange the wires from left to right so the order

is orange/white, orange, green/white, blue, blue/white, green, brown/white,

brown. They need to be arranged in a specific order to be properly crimped to

the RJ-45 connector.

4. Trim the

wires 1⁄2 inch (13 mm) away from the

sheath. Bring the wires together and hold them with your thumb and

index finger. Then, use your scissors to cut them. Make sure they’re cut evenly.

·

The

wires need to be even in order to fit into the grooves in the connector.

·

If

you cut the wires unevenly, move further down and cut them again so their ends

are in a straight line.

5. Fit the wires into the grooves of the RJ-45 connector. Hold the connector so the metal pins or brackets

are facing up and the clip is facing down. Hold the small wires together in the

right order and slide them into the connector. They should fit into the grooves

of the connector, with the end of the sheath of the cable fitting just past the

base of the connector.

6. Press the pins down with a flathead screwdriver. Locate the small metal pins at the ends of the

grooves of the connector. Use a thin, flathead screwdriver to push each of the

pins down. Push the pins 1 by 1 so they’re pressed all the way into each wire.

·

Be careful not to crack or break the plastic

connector.

7. Tug on the

end of the connector to make sure it’s secure. Double

check that all of the pins are pressed into the wire, and give a light tug on

the connector to make sure it won’t slide off. Each of the pins should be

inserted at the same level to form an even line.

·

Lightly shake the cable and listen for any rattling

that could indicate that one of the pins isn’t secure.

Comments

Post a Comment